|

Line setup wizard |

|

Line setup wizard |

The line setup wizard is intended principally for mooring analyses. It adjusts the configuration of multiple lines to achieve a given tension, declination or layback, specified individually for each line included. The wizard is available when the current simulation is in reset state and may be opened from the Calculation | Line setup wizard menu item.

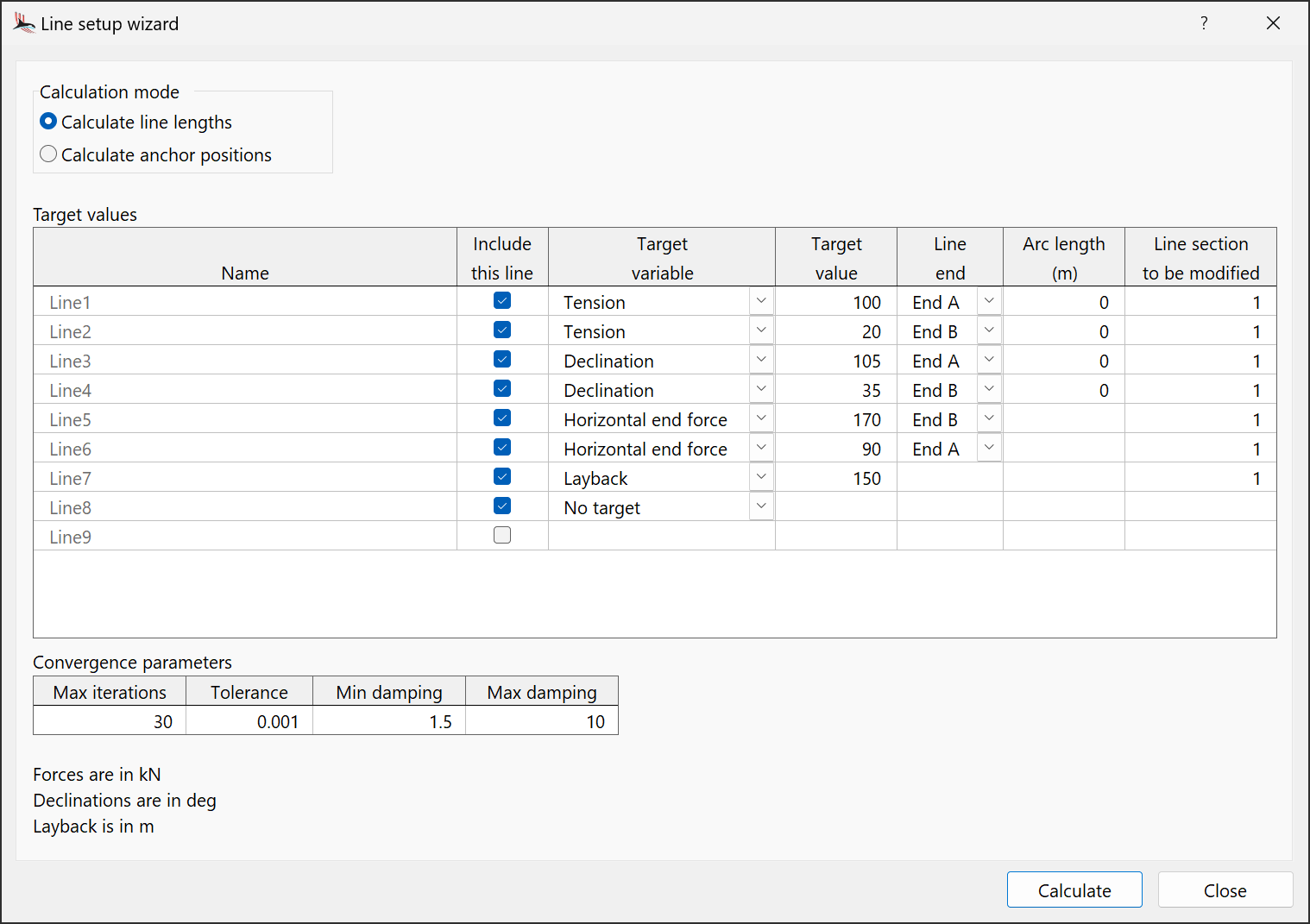

| Figure: | The line setup wizard |

The wizard has two modes of operation: Calculate line lengths or calculate anchor positions.

The calculate line lengths mode operates by adjusting the length of the specified section of each included line until the target value is achieved. As this mode changes the section length, we recommend that you specify the segmentation by target segment length rather than number of segments. In this way, if the wizard lengthens the line, then more segments are added automatically to maintain the target segment length.

The calculate anchor positions mode adjusts the bottom end position of each included line until the target value is achieved. The bottom end position is constrained to be along a line in the lay azimuth direction, so you must set this value for each included line before using the wizard.

| Note: | These calculations use a numerical method which is not 100% robust. We recommend that you set up your model so that your starting conditions have target values that are quite close to your exact target values before using the wizard. If you do this, the wizard is more likely to be able to find a solution. |

To use the wizard you must tell it which lines to configure, and define a target variable and value for each.

Include this line determines which lines are included in the calculation. The wizard presents a list of all lines in the model, allowing you to exclude certain of them. For example, you may be modelling both moorings and flow lines and wish to include only the moorings.

The target variable may be any valid results variable, including user defined results.

If no results variable is specified, i.e. the target variable is the empty string, then this will be interpreted as there being no target. The line will be included in the statics calculation but its data will not be modified. This is particularly useful if you are analysing buoyed systems where the upper and lower catenaries are modelled with different lines.

When a target variable is specified, you must also define a corresponding target value.

A tolerance value can be defined for each line which is used to determine when convergence is achieved, as described below. A value of '~' means that the overall tolerance defined in the convergence parameters will be used.

You must also define where on the line the target variable is calculated, using the line end and arc length fields. The arc length is measured from the given line end.

Specifies which section of the line is to have its length adjusted in the calculate line lengths mode.

The wizard performs an iterative calculation, and these parameters can be useful to help convergence in difficult cases.

The calculation is abandoned if convergence has not been achieved after the number of steps specified by max iterations. Sometimes, simply increasing this limit may be enough.

The tolerance parameter determines when the calculation is deemed to have converged. Convergence is achieved when the following condition is satisfied for each line with a target: \begin{equation} |\text{calculated value} - \text{target value}| \lt \text{tolerance} \end{equation}

The tolerance value is either the value specified for the individual line, or the overall convergence tolerance if the individual line tolerance is '~'.

| Note: | The convergence condition above is a dimensional equation. This means that you may need to take care to choose tolerances that are appropriate for the corresponding target variable. |

Changing the min damping and max damping parameters may sometimes help to help difficult problems converge. If necessary, try increasing the min damping factor to a value in the range 1.5 to 10, and/or increase the max damping factor to something in the range 10 to 100, say.

The line setup wizard can be executed in automated fashion either through the InvokeLineSetupWizard batch script command or from the OrcaFlex programming interface.